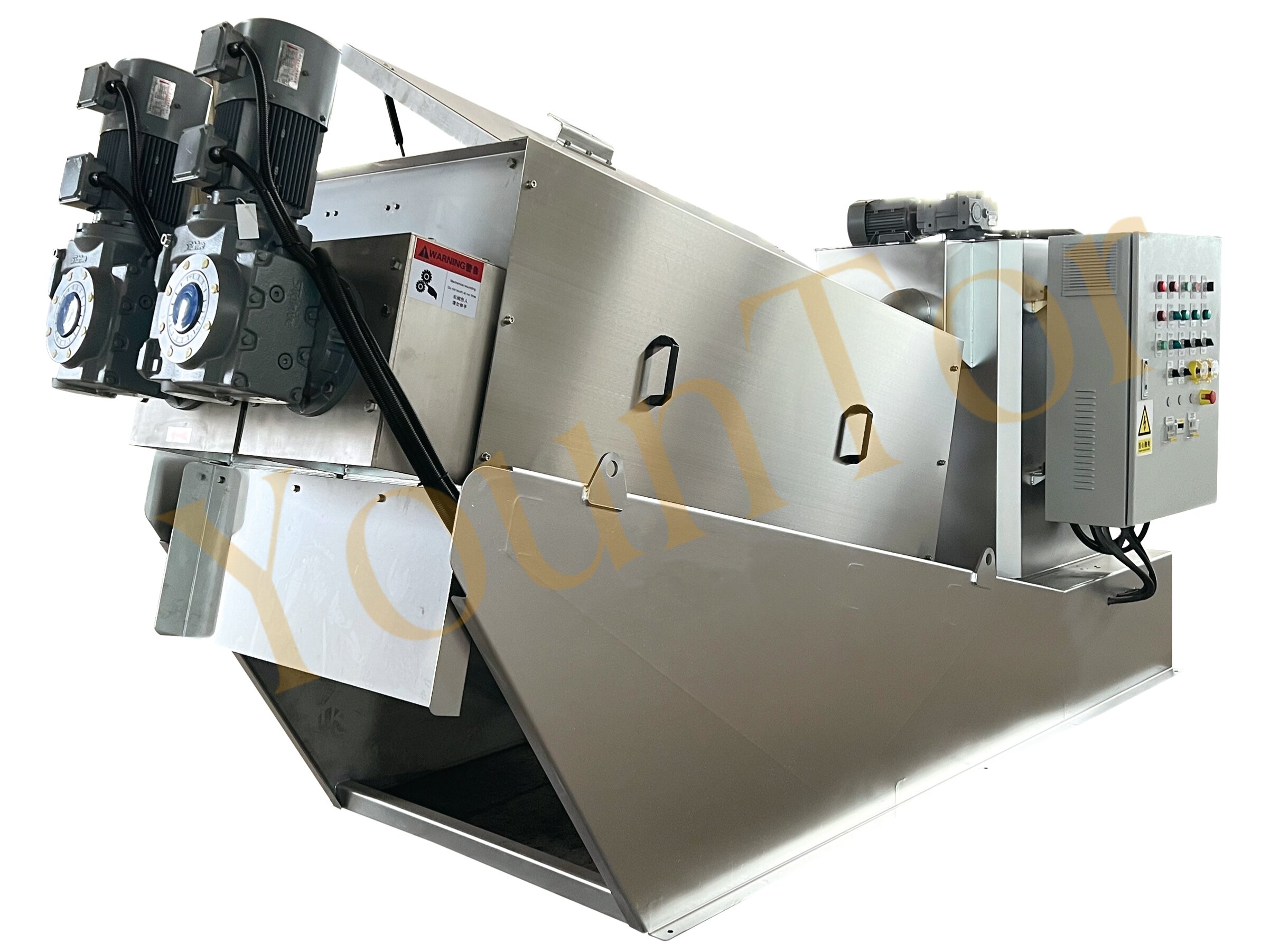

Multi-disc Screw Press Sludge Dewatering Machine, it's clog-free and can reduce the sedimentation tank and sludge thickening tank, saving the cost of sewage plant construction. Using screw shaft and moving rings to clean itself as clog-free structure, and controlled by the PLC automatically. It's a new technology that can replace the traditional filter press like belt press and frame press, the screw speed is very low, so it cost low power and water consumption in contrast to the centrifuge, it is a cutting edge sludge dewatering machine.

Sludge Dewatering Machine Description

Multi-Disc Screw press (MDSP) is a sludge dewateing machine of solid-liquid separator, which Screw Press Type can realize the Sludge dewatering or Sludge Dehydrator effect. The wastewater sludge is thickened and dewatered progressively along with Screw Press sludge dewatering the movement of the free rings, and ending by the rotary filter Screw Press plate. The sludge dewatering equipment special tungsten carbide coating of the inner screw and the sludge dewatering system slow rotation eliminates the friction effect and assure the dewatering screw a long life span of the parts. The Sewage Treatment sludge dewatering machine system of filtrate is drained from the gaps between the rings, which differs from the sludge thickening and the sludge dewatering zones. The sludge cake is discharged at the end plate, achieving a minimum solid content of 20%. The MDSP Screw Press dehydrator make it a self-cleaning unit due to the friction free movement between the rings, applicable for a wide range of sludge concentration (8000 mg/L – 50000 mg/L), and it’s most suitable for oily sludge treatment plant, and this sludge dewatering unit can be widely used in municipal wastewater, food, beverage, slaughtering breeding, printing and dyeing, petrochemical, papermaking, leather, pharmaceutical and other industries of sludge dewatering. It can be used in place of a belt press, decanter, or filter press.

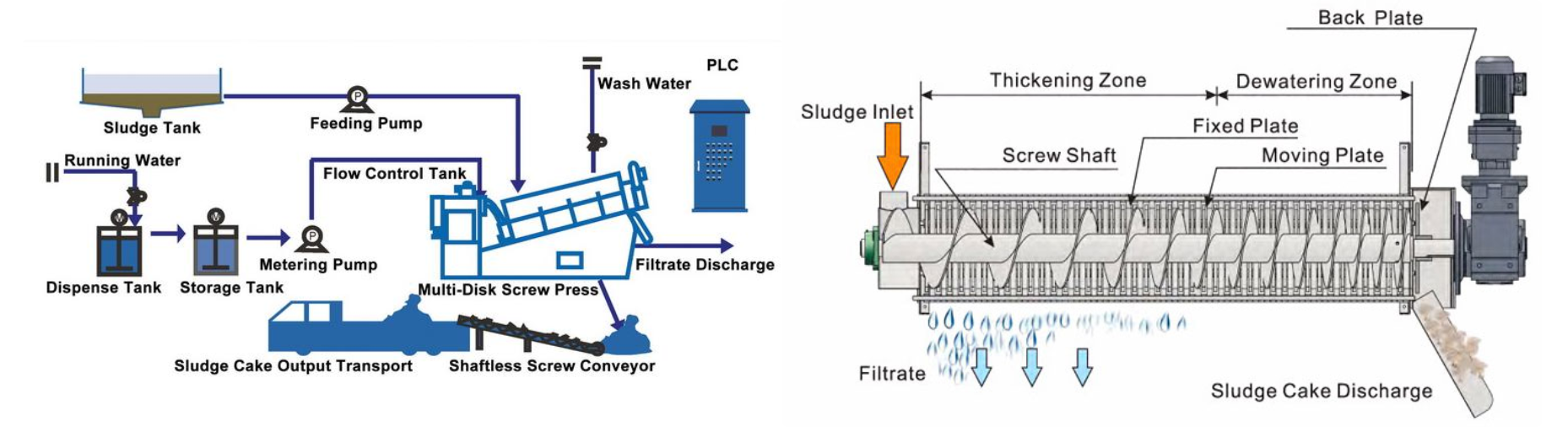

Working Principle

Screw Sludge dehydrator Layers of spacers, fixed and free rings are secured in place by rods. The screw press inner diameter of the free rings are slightly smaller than the screw major diameter, laying on the screw crest & continuously moving up and down following the screw Press rotation, & creating multi disk screw press a self cleaning effect. The screw Press pitch & the zone in between becomes smaller towards the end plate of sludge dewatering machine , which gives pressure to dewater the sludge.

Multi-disc screw presses are perfect for the dewatering of municipal and industrial sludge. We offer these devices in single, double and triple screw versions, with a diameter of 170 to 520 millimeters and a throughput of up to 20 m3 / h. The devices are delivered as a package with an automatic polyelectrolyte station and a dynamic flocculator. The main advantage of the multi-disc screw press is affordable operating costs related to low energy consumption, low consumption of reagents and practically negligible water demand. The device is also recommended for dewatering sludge, which contains a high dry matter content, so they can also be used in industry. An additional advantage of the product is the structure itself - closed and compact, occupying a small area.

In the initial stage of dewatering, the filtrate is clean and does not require further treatment before it is discharged into the sanitary sewage system. At the end of the device, due to the intense squeezing of the sludge, the filtrate usually contains a larger amount of suspended solids. Therefore the MDSP screw press, where necessary, is equipped with a separate dirty filtrate chamber and a circulation pump returning this filtrate to the beginning of the dewatering system. Thanks to this solution, the filtrate reaching the outflow is characterized by a small amount of suspended solids.

The use of movable discs, between which the water flows, allows for self-cleaning. The sludge dewatering process itself on the MDSP screw press does not require constant washing water consumption.

The press housing and discs are made of AISI 304 (1.4301) steel as standard. In order to protect the screw against abrasion, it is hardened with tungsten carbide to a value> 70 HRC.

The press control panel provides automatic operation, during which the following functions are performed: control of the screw rotation speed, the flocculator stirrer, periodic flushing of the outer surface of the rings, feeding of the sludge and polyelectrolyte (when the press cooperates with the polymer dosing station).

Advantages:

● Enclosed to minimize odors and noise

● Very low wash water usage(1/8 compared with belt press)

● Very low power consumption(1/20 compared with centrifuge)

● High cake solids

● Minimal operator requirement

● Easy to operate and maintain

● Auto start-up, run and shutdown

● Touch screen operation optional

● Sludge Flow and Cake Monitoring System

● Available with many other options like Dairy, Palm Oil, etc.

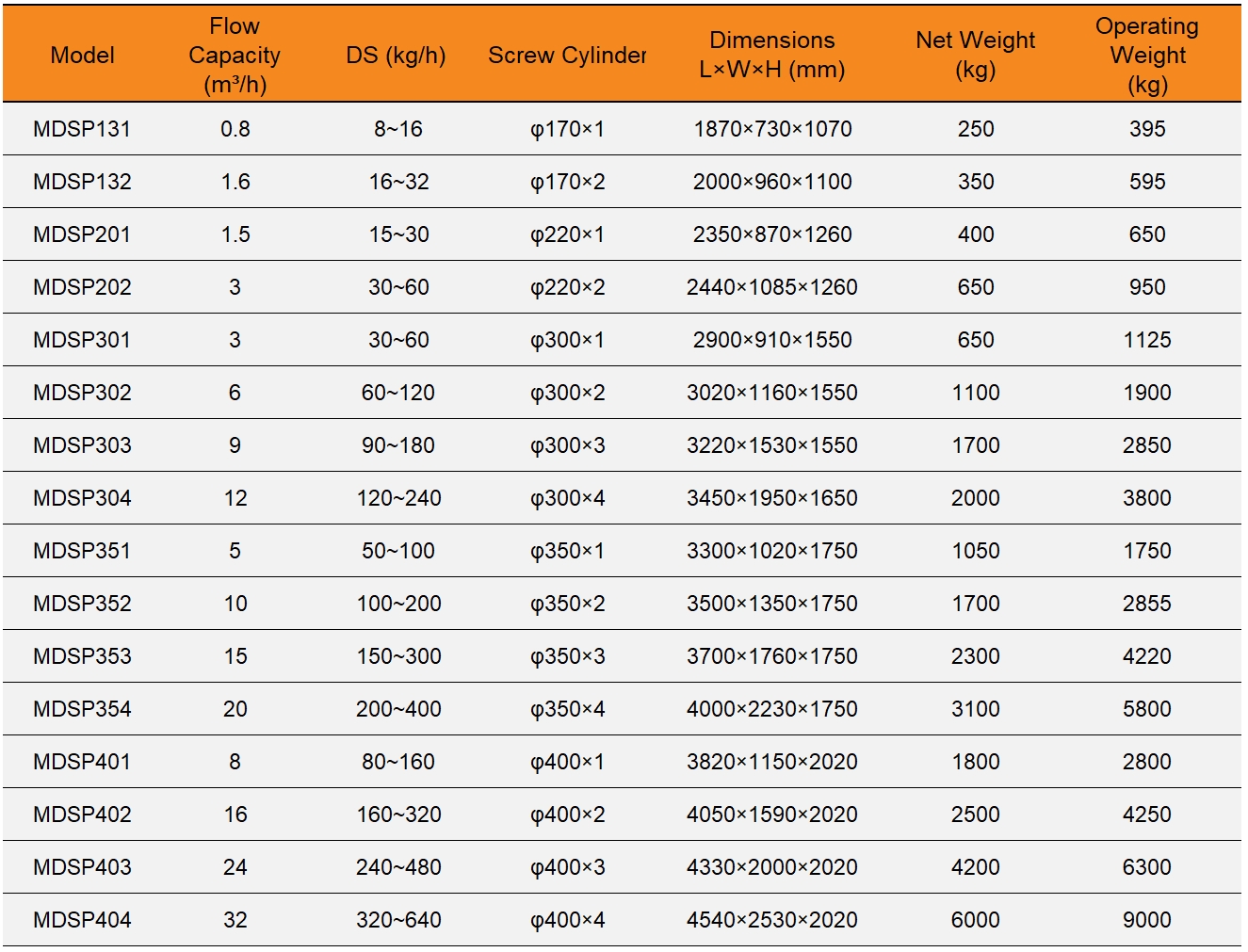

Parameters for Model Choice:

Contact: Ms.Ada

Phone: +86 189 5269 7883

E-mail: sales@yountortech.com

Whatsapp:+86 189 5269 7883

Add: Yangzhou City, Jiangsu, China

We chat